Homework: How to patch a plaster wall

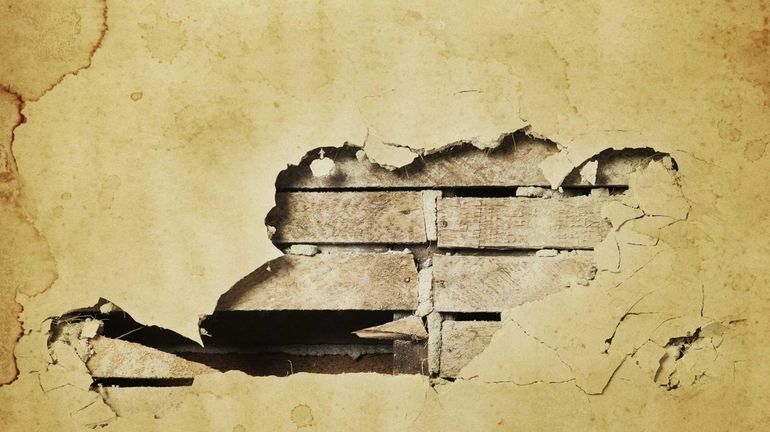

A grungy wall with a big hole in it, showing the lath and plaster. Credit: iStockphoto.com

If you own an older home that's got real plaster walls and ceilings, you'll discover quickly that traditional drywall premixed joint compound will not work well to fill larger holes. You need to use different materials. Fortunately, they're readily available and not too hard to work with.

Degree of difficulty: Three hammers out of five

Only 25¢ for 5 months

If you own an older home that's got real plaster walls and ceilings, you'll discover quickly that traditional drywall premixed joint compound will not work well to fill larger holes. You need to use different materials. Fortunately, they're readily available and not too hard to work with.

Degree of difficulty: Three hammers out of five

STEP ONE

Gather the following supplies: one 50-pound bag of Structo-lite and a 25-pound bag of Durabond 90 dry-setting joint compound. Dust off all your normal drywall finishing tools: mud pan, 6-inch taping knife, 10-inch broadknife, grout sponge, several buckets, a hand pad sander and a carpenter's framing square.

STEP TWO

Remove any loose plaster from the area you're going to repair. Very old homes had thin wood lath strips nailed to the wall studs and ceiling joists. Homes constructed just before World War II and after usually had 3/8-inch by 16-inch by 48-inch-long pieces of plaster lath board that covered the wall studs and joists. The plaster lath was the precursor to larger sheets of drywall used in today's new homes and remodeling jobs.

STEP THREE

Be sure the wood lath strips are securely nailed to the wood framing. The same is true if you have plaster lath. Both of these are the foundation to the plaster and they must be sound. If you have to install new plaster lath, you can purchase 3/8-inch thick drywall and cut it to fit the opening you have.

STEP FOUR

Traditional plaster was a two-stage process in which the master plasterers put on a base coat of sanded plaster that was a mixture of medium sand, hydrated lime and a little Portland cement. The addition of the Portland cement is one reason plaster is so hard because, in essence, you have a thin sheet of concrete on your walls and ceilings. Your new base coat to fill deep holes will be the Structo-lite.

STEP FIVE

Mix the Structo-lite as instructed on the label of the bag. Make sure the hole you're filling has all loose material out of the way, and dust off the area to be patched. I've always had great success spritzing the area to be patched with some clear water to slightly dampen the hole. This will help the Structo-lite bond to the old plaster.

STEP SIX

Use your smaller taping knife to fill the hole in the plaster. You want the finished surface of the sandy Structo-lite to be 1/8-inch below the surface of the finished plaster. Use the carpenter's square to span across the good plaster on the sides of the hole to ensure there's a gap between the square's edge and the fresh Structo-lite.

STEP SEVEN

Allow the Structo-lite to set up. Depending on the temperature, it can get stiff within a few hours. Read on the label of the bag when you can safely coat over it with the finish material. You might want to do this within eight hours or less. The sooner you do, the better chemical and mechanical bond you'll get between the Structo-lite and the Durabond 90.

STEP EIGHT

The Durabond 90 is a powder you mix with water. It's not as hard once cured as true white-lime plaster, but I doubt you can work with real plaster. It's a craft and requires practice and training. The Durabond 90 will produce a gorgeous smooth finish that will match the existing plaster, and it's sandable. Real white lime plaster can't be sanded because it's so hard.

STEP NINE

Mix the Durabond 90 with cold water to extend the working time. You apply this as you would normal drywall joint compound. Mix it to the consistency of warm cake icing. Try to put it on over the Structo-lite so it's extremely smooth and free of surface defects. Be sure it's in the same plane as the surrounding plaster. You can always add more, but remember it's hard and messy to sand off extra.

Summary: The Durabond 90 can be wet-sanded as it starts to harden in about 90 minutes after mixing. You can use the grout sponge to do this. It just requires very light strokes or circular rubbing. If you try to sand too early, you'll make an indentation in the Durabond 90. Once you get the hang of working with the sponge, you'll love how you can sand it without dust. Use your pad sander as a last resort if you mess up the wet-sand process.

Get Tim Carter's free weekly newsletter -- tool reviews, new product reviews, home-improvement tips and much more, delivered via email. Go to AsktheBuilder.com to sign up.